HomeTechnical Training Labs

Technical Training Labs

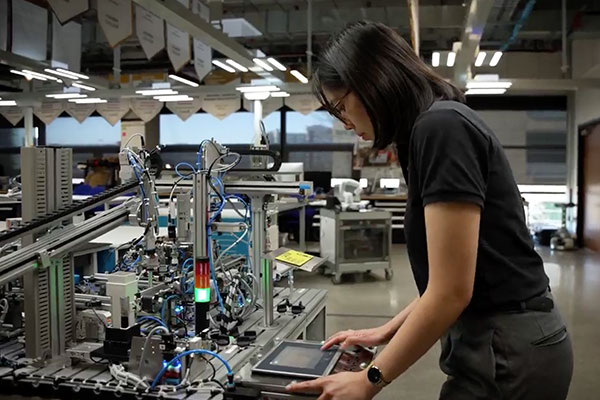

Build the Future with Hands-On Robotic Training Labs

From basic coding to advanced robotic arm simulations — we design labs that prepare learners for tomorrow’s tech-driven careers.

Inspiring Innovation at Every Stage of Learning

Harqo is a premier provider of advanced technical training solutions, committed to bridging the gap between academia and industry. With over the years of expertise, we excel in establishing Centres of Excellence in Additive Manufacturing, Automation, Mechatronics, and Robotics, fully aligned with Industry 4.0 standards. Our state-of-the-art training labs empower educational institutions and organizations to drive innovation, foster research, and deliver practical, hands-on learning. Recognized by government bodies such as MSME and NSIC, Harqo ensures access to the latest technologies, world-class equipment, and expert guidance—developing industry-ready talent and enhancing employability for the workforce of tomorrow.

Hands-On Learning

Build, program, and innovate using real-world robotics kits and tech projects that spark curiosity and creativity.

Future Skills

Master essential 21st-century skills in robotics, AI, IoT, and automation — preparing learners for careers of tomorrow.

Expert Training

Get guided by certified trainers who equip both students and educators with industry-aligned, practical knowledge.

Innovative Environment

Experience a dynamic lab setting that fosters collaboration, creativity, and critical thinking through hands-on technology.

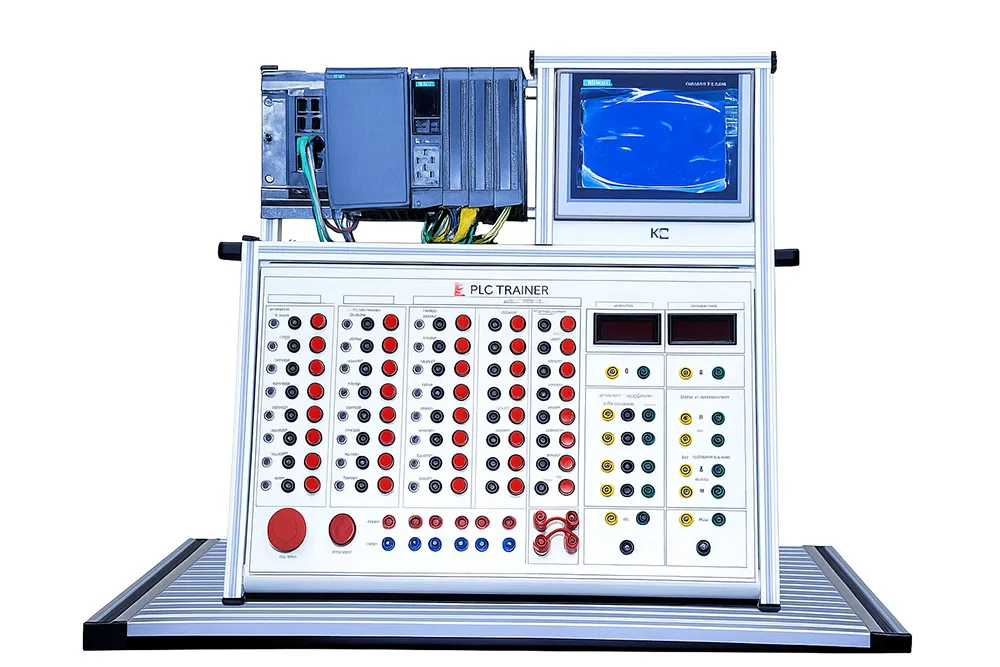

1. Industrial Automation Lab

The Industrial Automation Lab offers practical training on automation systems using Siemens PLC, SCADA, HMI, VFD, and Servo Drives. Students learn to design, program, and operate automation solutions replicating real industrial environments. This lab bridges the gap between theoretical knowledge and industry requirements, preparing students for careers in smart manufacturing and automation sectors with comprehensive exposure to modern automation tools and control systems.

2. Sensor Technology Lab

3. Industrial Pneumatic Lab

4. Industrial Hydraulic Lab

5. Industrial Mechatronics Lab

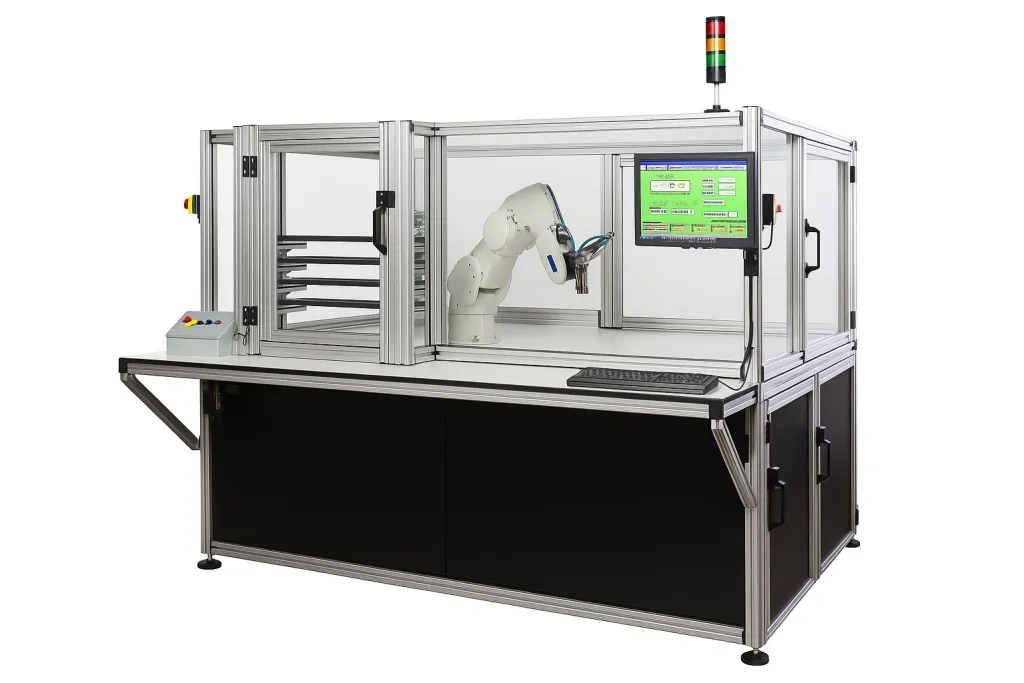

6. Industrial Robotics Lab

7. AR and VR Technology Lab

8. AI and Machine Learning (AIML) Lab

Hi Interested? Book a FREE Demo

Equip your institution with future-ready Robotics & AI Labs — spark innovation, empower learners, and shape tomorrow’s workforce today.